Top China Manufacturer of Building Lift Elevators for Your Projects

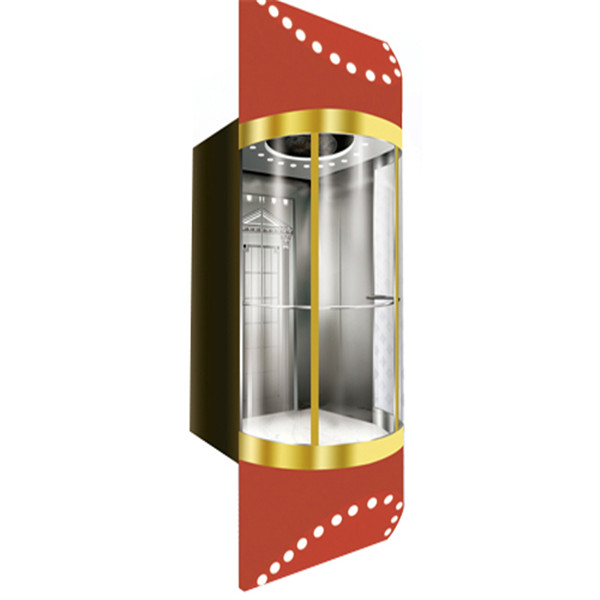

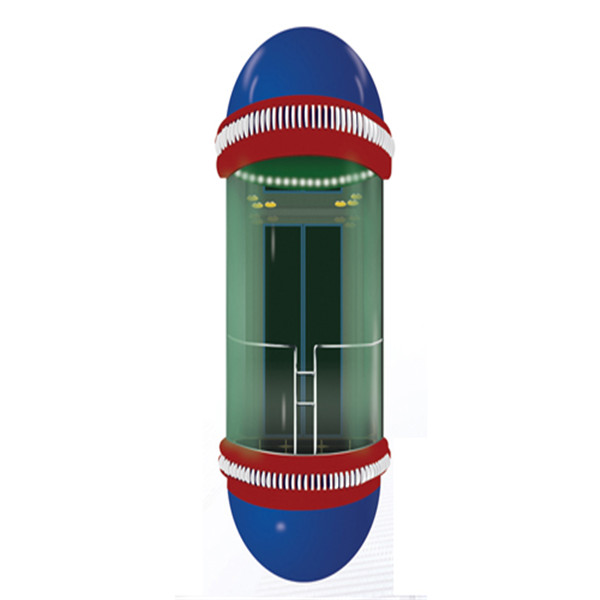

When it comes to building lift elevators, I understand the importance of choosing a reliable supplier. As a seasoned buyer, I seek out manufacturers in China who can provide high-quality, durable elevators that meet international standards. The technology and craftsmanship of Chinese manufacturers are impressive, ensuring that each building lift elevator is efficient and safe for all users. I emphasize the need for custom solutions that align with my project’s specifications, and I’ve found that working with top manufacturers in China allows for flexibility and innovation. The competitive pricing without sacrificing quality is a major draw, making these elevators a smart choice for any business. If you are in the market for robust and efficient building lift elevators, I can confidently recommend exploring the extensive options available from renowned manufacturers in China. It’s time to elevate your projects with state-of-the-art solutions designed to enhance user experience and productivity.

Building Lift Elevators Ahead of the Curve From Concept to Delivery

In today's rapidly evolving construction landscape, staying ahead of the curve is essential for the development and delivery of high-quality lift elevators. From the initial concept to the final product, integrating innovative designs, advanced technology, and sustainable practices is crucial for meeting the diverse needs of global buyers. This approach not only optimizes performance and efficiency but also addresses the growing demand for eco-friendly solutions in urban environments. The journey begins with collaboration, as designers and engineers work closely to transform visionary concepts into actionable plans. Utilizing cutting-edge simulation technologies and design software, the entire process becomes more streamlined, allowing for real-time adjustments that enhance reliability and safety. Once the design is solidified, automation and precision manufacturing techniques ensure that every elevator is built to the highest standards, ready to perform in even the most demanding conditions. Moreover, our commitment to customer service and after-sales support ensures that procurement partners receive unparalleled assistance throughout the lifecycle of the elevator system. By focusing on quality and continuous improvement, we can provide global buyers with products that not only meet but exceed their expectations, solidifying long-term partnerships and paving the way for future innovations in vertical transportation.

Building Lift Elevators Ahead of the Curve From Concept to Delivery

| Phase | Description | Duration | Key Technologies | Challenges |

|---|---|---|---|---|

| Concept | Initial design ideas and requirements gathering | 2 months | CAD Software, Simulation Tools | Defining requirements accurately |

| Design | Detailed engineering drawings and specifications | 3 months | 3D Modelling, Structural Analysis | Compliance with safety standards |

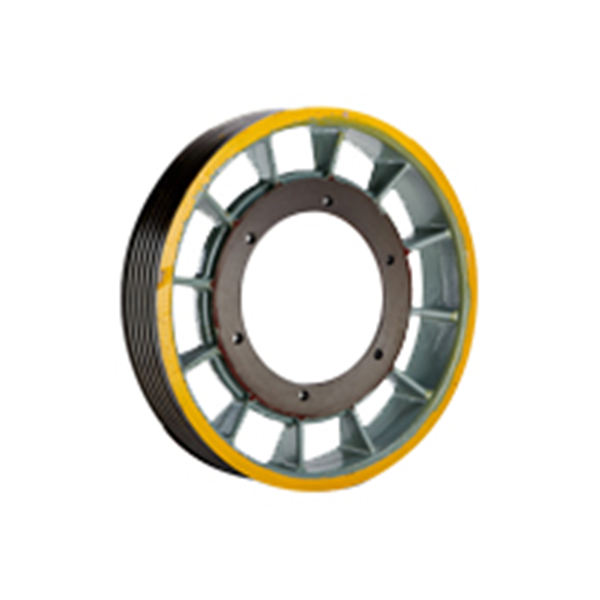

| Prototype | Construction of a working model for testing | 4 months | Prototype Materials, Testing Equipment | Material selection and testing accuracy |

| Testing | Functional and safety testing of the prototype | 2 months | Safety Standards, Performance Testing | Meeting regulatory requirements |

| Production | Mass production and assembly of elevators | 6 months | Automated Manufacturing, Quality Control | Supply chain management |

| Delivery | Installation and handover to the client | 1 month | Installation Software, Logistics | Coordination with site conditions |

Related Products