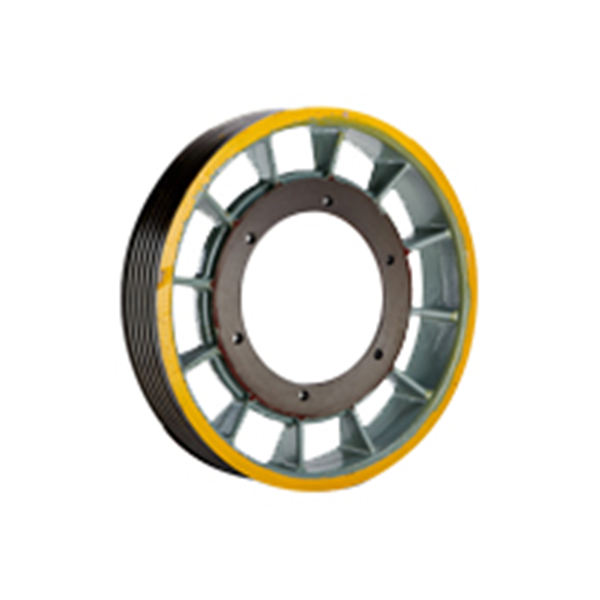

Elevator Wheel Roller Manufacturer in China - Quality & Efficiency

As a B2B purchaser, I know how crucial it is to find reliable accessories that enhance operational efficiency. That's exactly why I’m excited about the Elevator Wheel Roller from a leading manufacturer in China. Crafted with precision, these rollers are designed to ensure smooth and secure elevator operations, minimizing downtime and maintenance costs. I’ve been impressed with the quality – made from durable materials that can withstand heavy loads, they offer unmatched longevity. Whether you're in the construction sector or managing high-rise buildings, these rollers are a smart investment. The competitive pricing from this manufacturer allows for cost-effective bulk purchasing, fitting perfectly for my project needs. Plus, the option for customization means I can get exactly what I need without compromising on quality. Overall, if you're serious about enhancing your elevator systems, I highly recommend considering these Elevator Wheel Rollers.

Elevator Wheel Roller in 2025 Winning in 2025

As the elevator industry evolves, the focus on innovative solutions and sustainable practices becomes more pronounced. In 2025, the demand for efficient and reliable elevator components, such as wheel rollers, will be paramount. These components not only enhance the performance of elevators but also ensure safety and longevity, which are critical factors for global procurement managers. With advancements in materials and design, the next generation of wheel rollers will be engineered to reduce friction, increase load capacity, and minimize noise, ultimately leading to higher operational efficiency. Furthermore, the rising trend of smart buildings demands that elevator systems integrate seamlessly with advanced technologies. This opens up opportunities for manufacturers to develop wheel rollers that are compatible with smart elevator systems, allowing for predictive maintenance and remote monitoring. As procurement professionals explore suppliers, they will seek partners who not only provide high-quality products but also demonstrate an understanding of industry trends and technological advancements. In summary, navigating the procurement landscape in 2025 will require a strategic approach. Global buyers will benefit from selecting suppliers who are committed to innovation and sustainability. By prioritizing superior wheel roller mechanisms, businesses can ensure their elevator systems remain competitive, efficient, and ready to meet the demands of a rapidly changing world.

Elevator Wheel Roller in 2025 Winning in 2025

| Dimension | Value | Trend |

|---|---|---|

| Material | Steel | Durable & Cost-Effective |

| Weight Capacity | 1500 kg | Increasing Demand for Higher Capacity |

| Average Lifespan | 10-15 years | Improved Technologies |

| Typical Applications | Residential and Commercial Buildings | Growing Urbanization |

| Maintenance Frequency | Every 6 months | Shift towards Predictive Maintenance |

Related Products