China Manufacturer of Oil Elevator Buffer Elevator Safety Parts

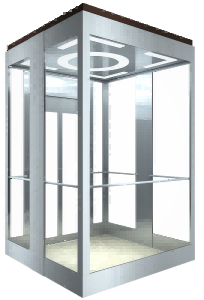

When I think about ensuring safety in oil elevator operations, I can't help but highlight the importance of reliable buffer elevator safety parts. As a manufacturer based in China, we specialize in high-quality components specifically designed to enhance the safety and efficiency of your elevator systems. Our parts undergo stringent testing to meet the industry's toughest standards, providing peace of mind for every operation. I understand the challenges that come with sourcing dependable parts, especially in a B2B environment where reliability is key. With our commitment to quality, we aim to deliver products that stand the test of time and ensure your elevators run smoothly. Whether you're upgrading existing systems or building new ones, our buffer elevator safety parts are tailored to meet your unique needs. Let's discuss how we can enhance your operations together and keep safety as a top priority in your business.

Oil Elevator Buffer Elevator Safety Parts Now Trending Your Trusted OEM Partner

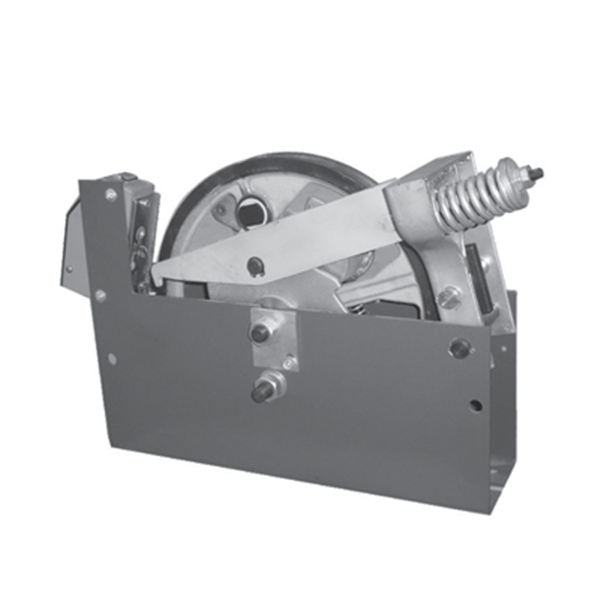

In the rapidly evolving world of elevator technology, the importance of safety components cannot be overstated. One key component gaining attention is the oil elevator buffer, which plays a crucial role in ensuring the safe and smooth operation of elevators. As advancements in engineering and materials science continue to progress, these buffers are designed to absorb shock and reduce noise, enhancing user comfort and safety. With a growing focus on efficiency and reliability, selecting the right OEM partner for these essential components is vital for businesses looking to optimize their elevator systems. As global demand for streamlined elevator solutions increases, partnering with a trusted OEM manufacturer is critical. Suppliers with expertise in producing high-quality safety parts not only ensure compliance with international standards but also contribute to the overall longevity and performance of your elevators. By choosing an experienced partner, procurement professionals can gain access to innovative designs and tailored solutions that meet specific operational requirements, ultimately leading to reduced maintenance costs and improved customer satisfaction. Moreover, with the shift towards sustainable manufacturing practices, the focus on eco-friendly materials and manufacturing processes adds another layer of significance to the selection of your OEM partner. Sustainability not only aligns with modern regulatory standards but also resonates with the growing consumer preference for environmentally responsible products. By investing in oil elevator buffer systems from a forward-thinking manufacturer, businesses can enhance their brand reputation while contributing positively to the environment. Embracing these advancements will not only ensure a competitive edge in the market but also promote a safer and more efficient future for elevator systems worldwide.

Oil Elevator Buffer Elevator Safety Parts Now Trending

| Part Name | Material | Weight (kg) | Dimensions (cm) | Application |

|---|---|---|---|---|

| Buffer Spring | Steel | 1.5 | 15 x 5 x 5 | Oil Lifts |

| Safety Sensor | Plastic | 0.2 | 10 x 5 x 3 | Elevator Control |

| Hydraulic Cylinder | Aluminum | 3.0 | 30 x 10 x 10 | Lifting Mechanism |

| Emergency Brake | Steel | 2.0 | 25 x 10 x 5 | Safety Systems |

| Control Panel | Plastic/Metal | 1.8 | 20 x 15 x 8 | User Interface |

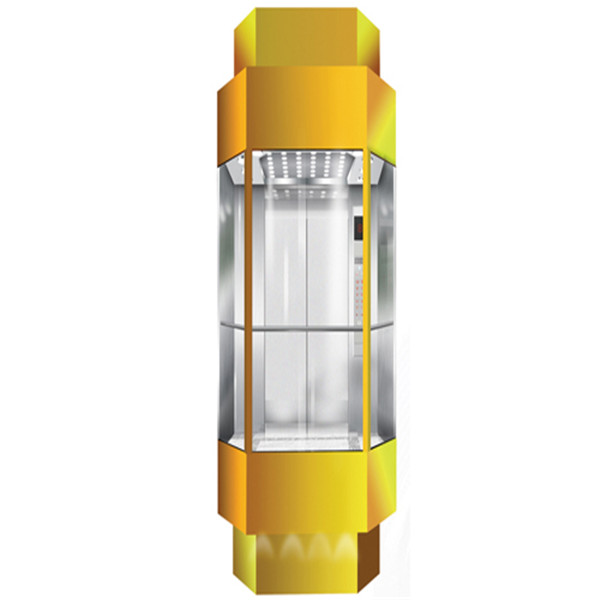

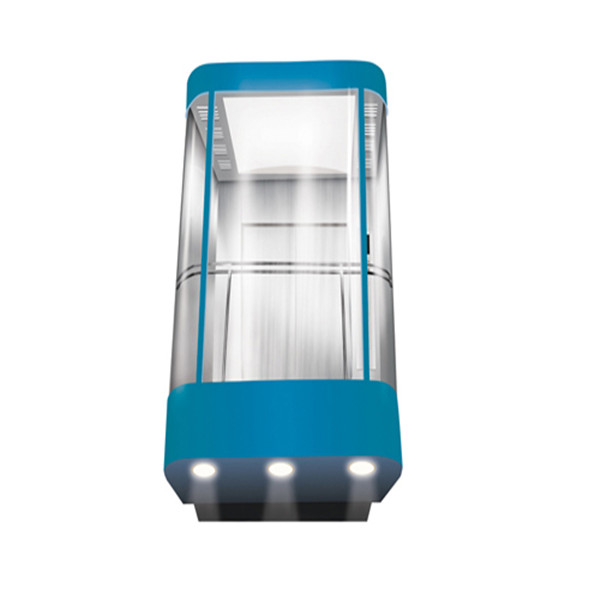

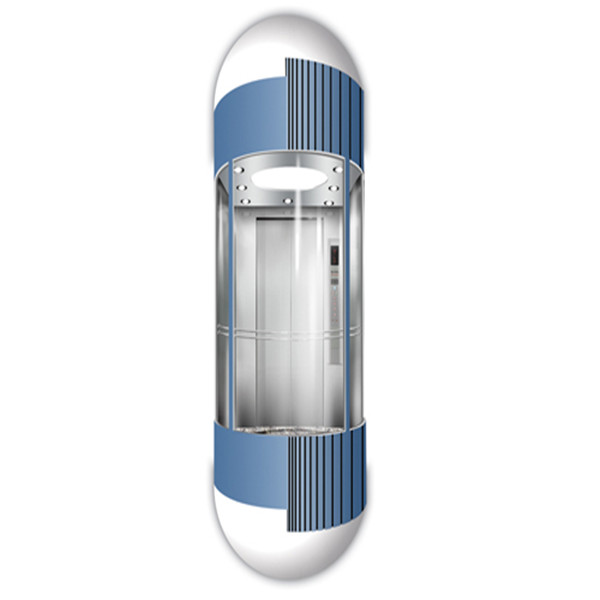

Related Products