- Getting started

- Escalator Comb Plate Escalator Center Kone Comb Plate Autowalk Comb Plates Travelator Comb Plate

China Manufacturer of Escalator Comb Plates & Travelator Comb Plates

As a dedicated manufacturer based in China, we specialize in high-quality escalator comb plates, including the Escalator Center Kone Comb Plate, Autowalk Comb Plates, and Travelator Comb Plate. Our products are designed with precision to ensure passenger safety and smooth operation. I understand the critical role that comb plates play in preventing accidents and maintaining escalator efficiency, which is why we employ advanced manufacturing techniques and rigorous quality control processes. I've seen firsthand how our comb plates stand out in durability and design, making them an ideal choice for any escalator system. With a focus on customer satisfaction, I strive to provide a range of unique options to meet diverse business needs. Our commitment to excellence and reliability distinguishes us as a trusted partner for B2B purchasers looking for top-notch escalator components. When quality and safety are your top priorities, our comb plates don't just meet expectations – they exceed them.

Escalator Comb Plate Escalator Center Kone Comb Plate Autowalk Comb Plates Travelator Comb Plate Guarantees Peak Performance More Than a Supplier - A Partner

In the fast-paced world of urban development and infrastructure, ensuring the safety and efficiency of escalators and moving walkways is paramount. High-quality comb plates play a crucial role in this ecosystem, acting as a protective barrier that enhances rider safety while ensuring seamless operation. Our advanced escalator comb plates, designed for both escalators and travelators, are crafted with precision engineering to guarantee peak performance. These components not only prevent accidents by smoothening the transition between the step and the landing, but they also contribute to the overall longevity of the equipment. Investing in our escalator comb plates means choosing a partner who prioritizes innovation, quality assurance, and customer satisfaction over simply being a supplier. Our commitment to excellence ensures that each comb plate meets international safety standards and is built to withstand the challenges of daily use in high-traffic environments. By collaborating closely with our global partners, we refine our products to meet the evolving demands of modern architecture and urban design, establishing a legacy of safety and efficiency that you can trust. As a reliable ally in your procurement journey, we understand the critical importance of dependable, high-performance components. Our team is dedicated to providing personalized support and tailored solutions to help you succeed in your projects. Together, we can elevate safety standards and enhance the user experience in public spaces worldwide, ensuring that every ride is a smooth and secure one. Choose a partnership that goes beyond transactions; choose a collaboration that drives performance and innovation in your projects.

Escalator Comb Plate Data Overview

| Feature | Description | Material | Dimensions (mm) | Weight (kg) | Compliance Standards |

|---|---|---|---|---|---|

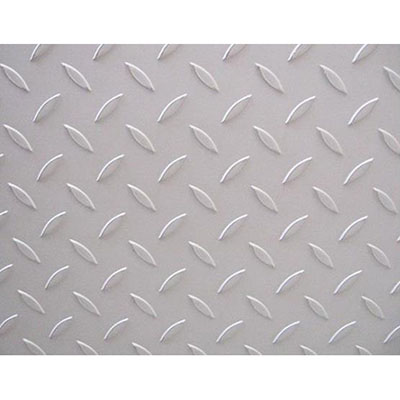

| Anti-Slip Surface | Enhances safety by preventing slips | Aluminum Alloy | 800 x 140 x 5 | 1.5 | EN 115, ISO 9001 |

| Durability | Resistant to wear and corrosion | Stainless Steel | 800 x 140 x 5 | 2.0 | EN 115, ISO 9001 |

| Customizable | Available in various sizes and designs | Plastic Composite | 800 x 140 x 5 | 1.2 | EN 115, ISO 9001 |

| Easy Installation | Designed for quick and efficient setup | Aluminum Alloy | 800 x 140 x 5 | 1.5 | EN 115, ISO 9001 |

Related Products