China Manufacturer of Schindler Door Machines & Elevator Motors

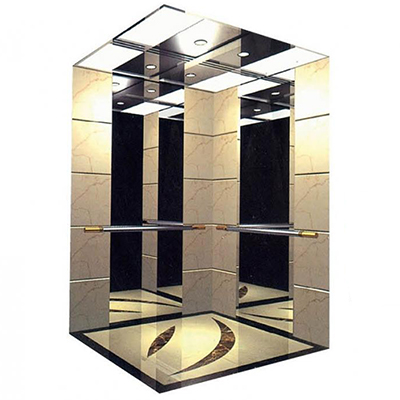

When you're in the market for reliable elevator components, I've found that the Schindler Door Machine, alongside the Schindler Elevator Door Motor and Fermator Elevator Controller, is a game changer. These products are engineered for optimum performance, ensuring smooth and efficient operation of your elevator systems. As a manufacturer based in China, we prioritize quality and durability, which means you can trust that each unit is built to withstand heavy-duty use. I've seen firsthand how our equipment stands up to the demands of busy commercial environments. What sets us apart is our commitment to customer satisfaction. Our technical support team is always ready to assist you, ensuring that you can maximize the value of your investment. Whether you're upgrading existing systems or installing new ones, these components are an ideal choice for any project. Let’s elevate your business with reliable solutions that you can count on!

Schindler Door Machine Schindler Elevator Door Motor Fermator Elevator Controller Service From Concept to Delivery

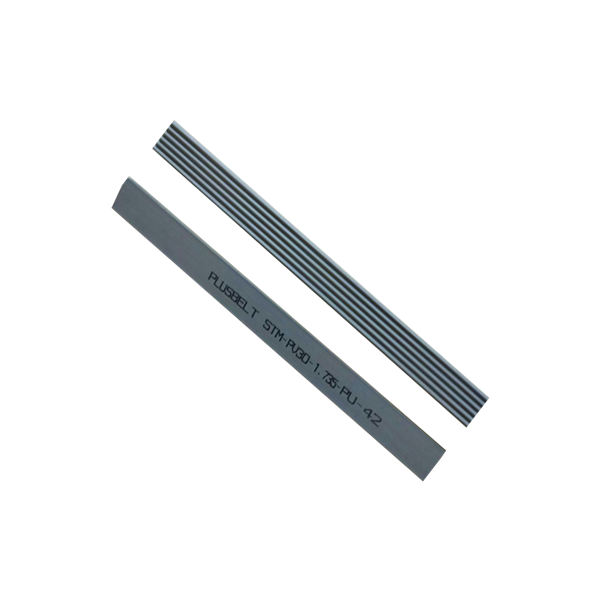

In the fast-paced world of vertical transportation, precision and reliability are paramount when it comes to elevator components. Elevators are not just about moving people and goods; they must do so efficiently and safely. Among the key components that ensure this functionality are door machines and motors. High-quality door machines, like those from Schindler, and precise elevator door motors play a significant role in the overall user experience. As global demand for advanced elevator systems rises, top-tier solutions are essential for manufacturers and service providers alike. Furthermore, modern elevator controllers, such as those offered by Fermator, provide sophisticated management of elevator operations, enhancing performance while maximizing energy efficiency. By integrating cutting-edge technology, these controllers streamline the entire operation from start to finish. They ensure that every ride is smooth and timely, meeting user expectations while minimizing wear and tear on the system. This synergy between robust door mechanisms and intelligent control systems guarantees a seamless travel experience for passengers. For suppliers seeking to enhance their offerings in the global market, investing in superior elevator components is no longer optional. It is a necessity for staying competitive. Partnering with a reliable provider means gaining access to a comprehensive portfolio of solutions, from concept development to final delivery. This ensures that every elevator system not only meets but exceeds international standards for safety, comfort, and performance.

Schindler Door Machine Schindler Elevator Door Motor Fermator Elevator Controller Service From Concept to Delivery

| Service Type | Description | Lead Time | Warranty Period | Compatibility |

|---|---|---|---|---|

| Door Machine Installation | Professional installation of elevator door machines with safety compliance. | 2 weeks | 2 years | Schindler, Fermator |

| Elevator Motor Repair | Repair services for elevator door motors ensuring efficient operation. | 1 week | 1 year | Fermator |

| Controller Upgrades | Upgrading elevator controllers for enhanced performance. | 3 weeks | 2 years | Schindler |

| Routine Maintenance | Scheduled maintenance to ensure optimal functionality of elevator systems. | Ongoing | N/A | All models |

| Emergency Services | 24/7 emergency repair services for elevator systems. | Immediate | N/A | All models |

Related Products