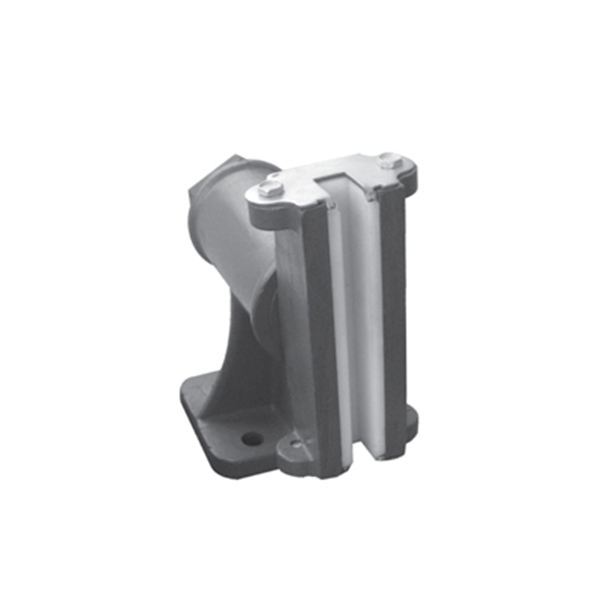

Top China Manufacturer of Elevator Oil Buffers for Optimal Performance

When I think about top-quality Elevator Oil Buffers, I immediately think of the reliable manufacturers in China. These products are designed to ensure smooth and safe operation in vertical transportation systems. With my experience in the industry, I know the importance of precision engineering and durability, which is exactly what you get from these buffers. They absorb shocks efficiently, enhancing the overall safety of your elevators. Working with a trusted manufacturer guarantees not just high performance but also compliance with international safety standards. Plus, sourcing products from China often means cost-effective solutions without compromising on quality. Whether you're upgrading existing systems or building new ones, choosing the right Elevator Oil Buffers can significantly improve your operational efficiency. Let's connect to explore the best options that meet your specific needs and elevate your business standards.

Elevator Oil Buffers Now Trending Guarantees Peak Performance

Elevator oil buffers have emerged as a crucial component in ensuring the smooth and safe operation of elevator systems worldwide. As demand for high-performance elevators continues to grow, so does the necessity for reliable components that can withstand various operational challenges. These buffers play a pivotal role in absorbing impact and minimizing vibrations, thus safeguarding both equipment and passenger safety. With advancements in technology, modern oil buffers are designed to offer enhanced efficiency and durability, aligning with the industry's trend toward sustainability and performance optimization. The trending use of oil buffers reflects a broader shift in the elevator industry towards higher standards and innovation. Manufacturers are increasingly aware of the importance of quality materials and engineering processes that not only meet but exceed regulatory requirements. Buyers in the global market are now prioritizing features such as temperature resilience, adaptability to different elevator models, and maintenance ease. Investing in top-notch elevator oil buffers is more than just a purchase; it's an investment in safety, reliability, and overall operational effectiveness. As businesses strive to improve their service offerings, incorporating high-performance components like oil buffers can significantly impact their operational success. For global procurement managers, understanding the trends and innovations in this space is critical in making informed purchasing decisions that align with the evolving needs of modern elevator systems.

Elevator Oil Buffers Now Trending Guarantees Peak Performance

| Dimension | Value | Unit |

|---|---|---|

| Maximum Load Capacity | 2000 | kg |

| Buffer Stroke Length | 50 | mm |

| Operating Temperature | -10 to 60 | °C |

| Response Time | 0.1 | s |

| Lifespan | 500000 | cycles |

| Material | Stainless Steel | - |

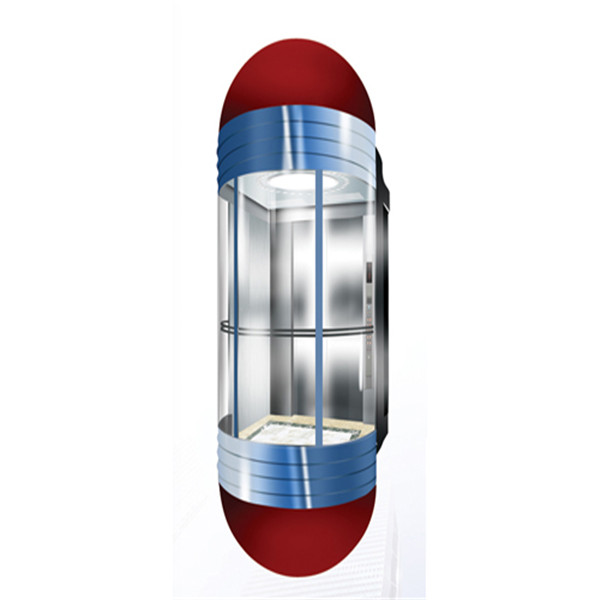

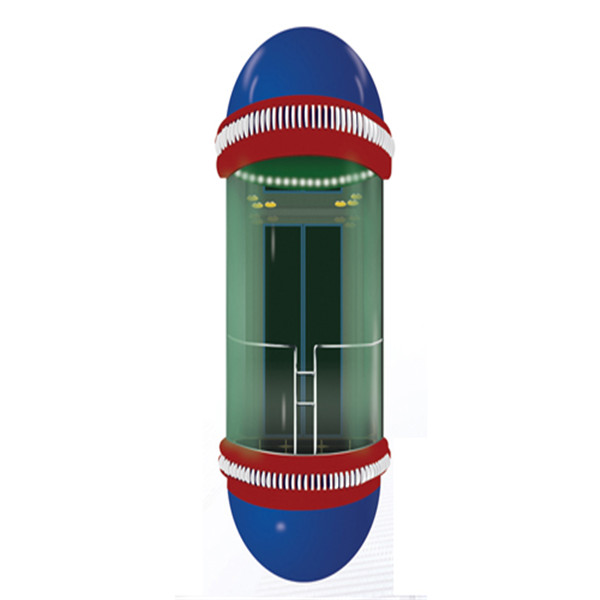

Related Products