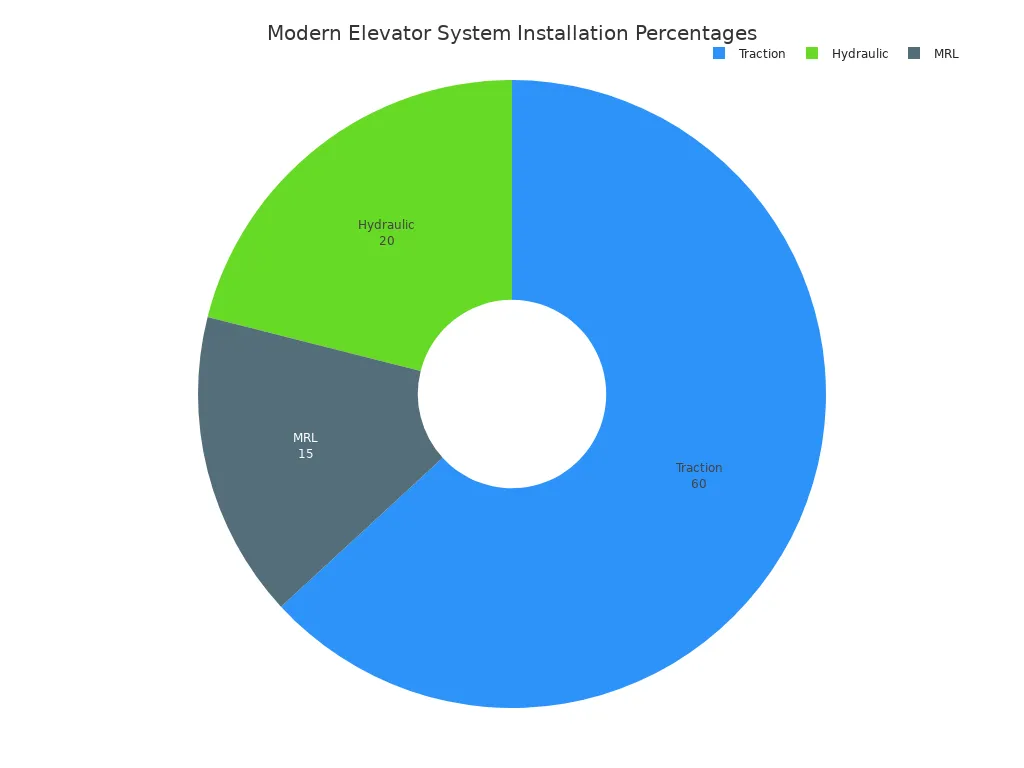

Understanding the distinct operational principles and applications of various elevator types is crucial. This knowledge helps in selecting the most appropriate vertical transportation system for any structure. Primary distinctions exist in their drive systems: traction, hydraulic, and machine-room-less (MRL) elevators. Each system offers unique benefits for specific building needs. Modern installations demonstrate the prevalence of these types.

Key Takeaways

- Traction elevators are best for tall buildings. They move fast and can go very high.

- Hydraulic elevators work well for short buildings. They use fluid to lift the car and are simple to install.

- MRL elevators save space. They put the machine parts inside the elevator shaft and are good for many modern buildings.

Traction Elevator Systems: The Workhorse of High-Rise Buildings

How Traction Elevators Operate

Traction elevator systems use a traction machine to pull wire ropes. This action causes the elevator car and its counterweight to move. The car and counterweight generate opposing traction forces during operation. When these forces balance, the elevator runs at a uniform speed. Imbalances, such as varying passenger loads, can lead to a non-equilibrium state. This can cause wire rope slippage if the static friction between the rope and groove is insufficient. The system includes a traction system, guiding system, door system, car, weight balance system, electric traction system, electric control system, and safety protection system.

A motor and pulley system moves the elevator cab vertically. Steel ropes attach to the cab. Counterweights offset the cab’s weight, reducing power consumption. These systems rely on friction for smooth movement. AC or DC motors can power them. Essential safety mechanisms, such as brakes and overspeed governors, ensure passenger safety. The drive machine powers movement, while the controller manages operations. The counterweight balances the cab’s weight, minimizing the power needed for vertical travel.

- Under normal conditions, the elevator moves at its designated speed. The governor sheave rotates accordingly.

- If the elevator car exceeds its safe operational speed, the centrifugal mechanism within the governor activates.

- When centrifugal force surpasses a preset limit, it triggers the governor switch. This cuts off power to the elevator motor and initiates an emergency stop.

- Simultaneously, the governor engages the safety gear on the elevator car. This firmly grips the guide rails to bring the elevator to a controlled halt, preventing free fall or excessive descent speed.

Geared vs. Gearless Traction Elevators

The primary distinction between geared and gearless elevator motors lies in their mechanical setup. Geared motors use a gear mechanism for movement control. Gearless motors operate via direct linkage to the drive sheave. This contributes to greater efficiency and quieter operation.

| Feature | Geared Traction Machines | Gearless Traction Machines |

|---|---|---|

| Mechanism | High-speed electric motor with a reduction gearbox, connecting to the drive sheave via a rotating shaft. | Drive sheave connected directly to a low-speed, high-torque electric motor shaft, eliminating the gearbox. |

| Torque/Speed | Gear system reduces motor speed and increases torque. | Direct drive provides ultra-smooth motion and high torque at low speeds. |

| Motor Type | Standard electric motor with a gearbox. | Often uses permanent magnet synchronous motors (PMSM) or wound rotor motors. |

| Speed Cap. | Typically up to 2.5 m/s. | Capable of speeds up to and above 10 m/s. |

| Machine Room | Traditionally requires a dedicated machine room. | Available in traditional machine room and machine-room-less (MRL) configurations. |

Key Characteristics of Traction Elevators

Traction elevators offer high speed and significant travel height.

- Geared traction elevators can achieve travel speeds of up to 500 feet per minute.

- The maximum travel distance for a geared traction elevator is approximately 250 feet. These systems are known for their efficiency and smooth ride, making them suitable for buildings with heavy traffic.

Ideal Applications for Traction Elevators

Traction elevators are widely used in mid- to high-rise buildings. They provide faster travel and greater efficiency. They suit heavy traffic and taller structures, including skyscrapers, large commercial buildings, hospitals, and offices. They excel in tall, high-traffic structures.

- Geared Traction Systems: Suitable for mid-rise buildings, with a height limit of up to 300 feet (30 stories).

- Gearless Traction Systems: Designed for high-rise buildings and luxury installations, with an unlimited height limit.

- General Traction: Recommended for buildings over five stories or when faster speeds are required.

Hydraulic Elevator Systems: Power and Simplicity for Low-Rise Structures

How Hydraulic Elevators Function

Hydraulic systems rely on fluid pressure instead of hoist ropes. The elevator car is supported by a piston at its base, which moves within a cylinder. A hydraulic pump injects pressurized oil into this cylinder. This action forces the piston to extend and lifts the elevator car. Releasing the fluid allows the elevator car to descend. These systems use incompressible fluids, such as oil, to transfer power efficiently.

Holed vs. Holeless Hydraulic Elevators

Holed hydraulic elevators feature a piston that extends beneath the elevator floor within a drilled hole. This piston retracts when the elevator descends. Some variations use a telescoping piston, requiring only a shallow hole, allowing travel up to 50 feet. Non-telescoping pistons may only rise up to 20 feet. Holeless hydraulic elevators do not require a drilled hole. They have pistons mounted inside the hoistway, often on either side of the cab. These systems generally achieve a travel distance of approximately 60 feet. Holeless machine-room-less (HMRL) hydraulic elevators place the power unit and jacks above ground within the shaft, eliminating the need for a drilled jack hole.

| Feature | Holed Hydraulic Elevator | Holeless Hydraulic Elevator |

|---|---|---|

| Structure | Hydraulic cylinders extend into a drilled hole in the ground; car mounted on a piston inside the cylinder. | Pistons mounted inside the hoistway; no drilled hole required. |

| Travel Distance | Up to 60 feet. | Up to 40 feet. |

| Suitability | Standard installations. | Ideal for existing buildings or areas where drilling is not feasible. |

Key Characteristics of Hydraulic Elevators

Hydraulic elevators offer a smooth ride and simple operation. They typically operate at lower speeds compared to traction systems.

| Type of Elevator | Speed (fpm) | Maximum Travel Height |

|---|---|---|

| Hydraulic Home | 20-25 | 50’ (up to 6 stops) |

| Hydraulic Passenger and Service (Roped) | 80, 100, 125, 150 | 98’ – 0” |

Ideal Applications for Hydraulic Elevators

Hydraulic elevators are best suited for low-rise buildings, typically those with five or fewer floors. They are a solid choice for structures with limited space because they do not require extensive overhead structures.

- Small Office Buildings: They offer straightforward installation and low-maintenance costs.

- Apartment Complexes: They provide a smooth ride quality and ease of maintenance.

- Boutique Hotels and Retail Spaces: Compact hydraulic elevators fit well where overhead machinery rooms are impractical.

- Medical Facilities and Shopping Centers: They provide reliable transportation with minimized disruption and operational costs.

Machine-Room-Less (MRL) Elevator Systems: Space-Saving Innovation

How MRL Elevators Work

MRL elevator systems integrate machine room components directly into the hoistway. This design eliminates the need for a separate machine room. A compact gearless traction machine often sits at the top of the shaft. This machine drives the ropes or belts that move the car. MRL systems offer exceptional ride quality.

- Exceptional Ride Quality: Polyurethane-coated steel belts eliminate metal-to-metal contact. This results in quiet and vibration-free operation.

- Precise Control: Sophisticated microprocessor-based control systems ensure accurate speed regulation. Variable Voltage Variable Frequency (VVVF) drives provide smooth acceleration, deceleration, and precise leveling.

- Regenerative Drive Technology: The gearless traction machine acts as an electrical generator. It captures energy when the car descends with a heavy load or ascends with a light load. This energy returns to the building’s electrical network. This significantly improves energy efficiency, offering 35-60% savings.

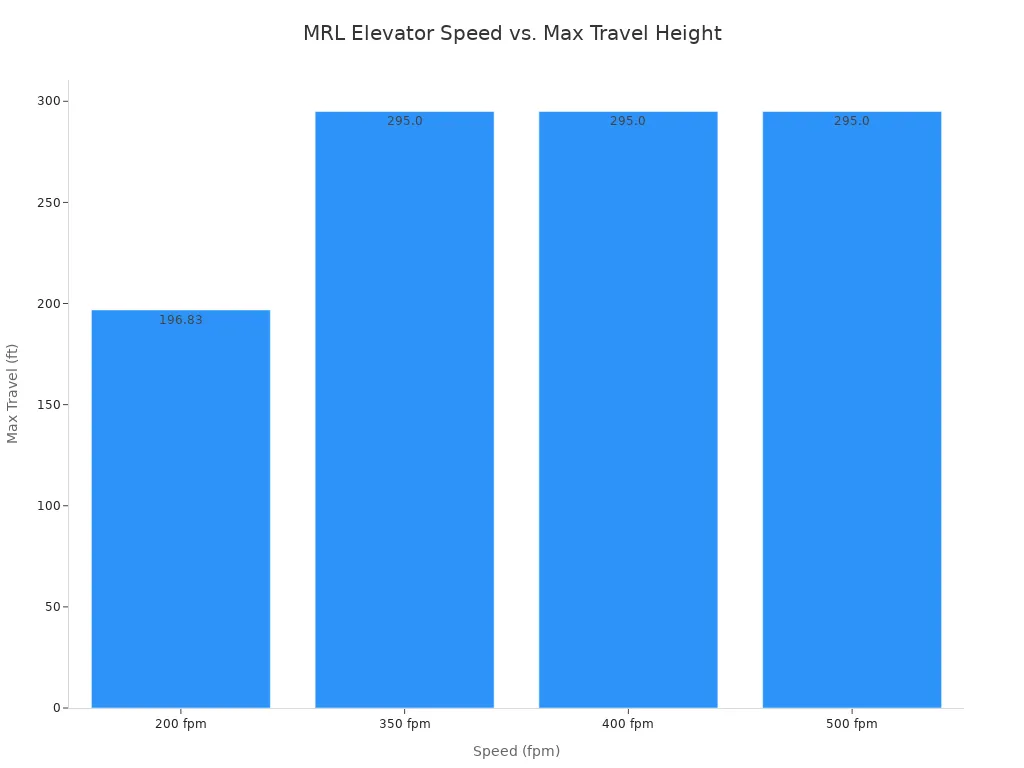

Key Characteristics of MRL Elevators

MRL elevators are known for their space-saving design and efficiency. They offer a balance of performance and environmental benefits. Their compact nature makes them versatile for various building types.

| Speed (fpm) | Max Travel (ft) |

|---|---|

| 200 | 196′ 10″ |

| 350 | 295′ |

| 400 | 295′ |

| 500 | 295′ |

|

|

| These systems provide speeds comparable to traditional traction systems in many applications. They also maintain a significant travel height. |

Ideal Applications for MRL Elevators

MRL systems are highly versatile. They suit many modern construction projects.

- Low-rise buildings (up to 33 feet of rise)

- Buildings with limited space

- Residential complexes Their compact footprint makes them ideal for structures where space is at a premium. They offer a modern, efficient solution for vertical transportation.

Other Specialized Elevator Types

Vacuum Elevators for Niche Residential Use

Vacuum elevators offer a unique solution for residential settings. These elevators operate using air pressure, eliminating the need for cables, pistons, chains, or counterweights. Their self-supporting structure requires no pit excavation, hoistway, or machine room, allowing installation within one to three days. They consume minimal energy during ascent and use no energy for descent. This design provides 360º visibility and requires minimal maintenance. Vacuum elevators are ideal for new and existing homes, marine applications, and stage setups. They operate on a 220V single-phase service and offer smooth starting and stopping.

Rack and Pinion Elevators for Heavy-Duty Sites

Rack and pinion elevators are robust systems designed for demanding industrial and construction environments. They move heavy loads efficiently and withstand harsh conditions like dust, moisture, and extreme temperatures. These elevators include safety devices that activate if the elevator exceeds a set speed, ensuring a safe stop. They offer high load capacities and provide consistent, reliable operation. Applications include:

- Construction Sites: Transporting personnel and materials on high-rise projects.

- Industrial Sectors: Used in power plants and shipyards for durable vertical transportation.

- Infrastructure Maintenance: Providing access in high-rise buildings for technicians.

- Mining Operations: Transporting personnel and materials in challenging terrains.

Dumbwaiters for Small-Scale Transport

Dumbwaiters provide efficient small-scale transport for items, not people. These systems feature sturdy carriages and pulley systems, streamlining goods movement and reducing manual handling. They optimize floor space as they can be installed in confined areas. Safety features include door interlocks and emergency brakes. Commercial dumbwaiters can transport up to 500 pounds, while residential models typically handle up to 200 pounds. They are widely used in:

- Hospitality: Moving food and dishes in restaurants and hotels.

- Healthcare: Delivering medical supplies and equipment in hospitals.

- Retail: Transporting merchandise and inventory.

- Residential: Moving groceries, laundry, and bulky items between floors.

Comparing Key Differences Among Elevator Types

Speed and Travel Height of Each Elevator

Elevator systems vary significantly in their speed and maximum travel capabilities. Hydraulic elevators typically operate at slower speeds. They have a suggested maximum up speed of 150 feet per minute. Geared traction elevators can reach speeds up to 500 feet per minute. Gearless traction elevators offer much higher speeds, capable of up to 2,000 feet per minute. Machine-Room-Less (MRL) traction elevators generally achieve speeds of 500 feet per minute. Some specific MRL models sold overseas can even reach 600 to 800 feet per minute.

Travel height also differs greatly among these systems. Hydraulic elevators are best for lower rises. Conventional hydraulic systems and roped hydraulic systems typically reach about 60 feet. Hole-less hydraulic elevators with telescoping pistons can travel up to 50 feet. Non-telescoping hole-less hydraulic systems have a more limited range, around 20 feet. Traction systems handle much greater heights. Geared traction elevators and MRL systems can travel around 250 feet. Gearless traction elevators are designed for the tallest buildings, reaching approximately 2,000 feet. For example, a Schindler 3300 MRL traction elevator has a travel height of up to 98 feet 5 inches.

| Elevator Type | Maximum Travel Height |

|---|---|

| Conventional Hydraulic | Approximately 60 feet |

| Hole-less Hydraulic (Telescoping) | Up to 50 feet |

| Hole-less Hydraulic (Non-telescoping) | About 20 feet |

| Roped Hydraulic | About 60 feet |

| Geared Traction | Around 250 feet |

| Gear-less Traction | Around 2,000 feet |

| MRL | Up to 250 feet |

Energy Consumption and Environmental Impact of Elevators

Different elevator types have varying energy demands and environmental footprints. Hydraulic elevators generally consume more energy. Their hydraulic pump operates continuously to maintain pressure, leading to higher electricity usage. Traction elevators, especially those with regenerative drives, use 15-30% less electricity than hydraulic systems. This makes them a more energy-efficient choice for many buildings.

Machine-Room-Less (MRL) elevators are particularly efficient. They use advanced motor and control technology. MRL lifts are generally more efficient than older, geared systems. Modern MRL elevators in a mid-rise building consume approximately 3.2–60 kWh per person annually over a 200-day working year. While MRLs offer significant energy savings during operation, they have a higher standby power requirement than hydraulic elevators when inactive. This means they use more power when not actively moving.

Installation and Maintenance Considerations for Elevators

Installation and maintenance requirements differ significantly across elevator types. Hydraulic elevators often have simpler installation processes. They do not require extensive overhead structures. However, they need regular checks for oil leakage and proper leveling. It is recommended that all passenger and freight elevators receive monthly visits. This ensures proper leveling function, door operation, and mitigates potential oil leakage or unforeseen issues. Most malfunctions relate to door function, making regular monthly inspections crucial.

Maintenance tasks for hydraulic elevators include specific checks of:

- Hydraulic valve systems

- Pumping units

- Pistons

- Tanks and reservoirs

- Additional smoke detectors and fire suppression systems

Traction elevators, due to their complexity, require more detailed maintenance. They need a minimum service frequency of 1 hour per month. Maintenance visits typically occur every 1 to 6 months, depending on the lift type, usage, and local regulations. Common maintenance tasks include:

- Regular inspections of mechanical, electrical, and safety systems

- Cleaning to prevent dirt and debris interference

- Lubrication of moving parts like gears and pulleys

- Testing safety features such as emergency brakes and door sensors

- Replacing worn or damaged components

- Software and control system checks and updates

- Periodic load testing to ensure capacity handling

Cost Implications of Different Elevator Systems

The cost of an elevator system involves both initial installation and long-term operational expenses. Machine-Room-Less (MRL) elevators have specific installation costs. For residential use, MRL elevators typically cost between $35,000 and $60,000 or more. Commercial MRL passenger elevators generally cost between $50,000 and $100,000 or more.

Long-term operational costs also vary. Hydraulic elevators have higher energy consumption due to the continuous operation of their pump. Their annual maintenance cost ranges from $1,000 to $2,000. Potential repair costs can be significant, with hydraulic fluid replacement and leak repairs adding $5,000 or more per incident. Traction elevators generally have lower long-term energy costs, especially with regenerative drives. Their annual maintenance cost ranges from $1,500 to $3,000. Overall, traction elevators are often more cost-effective over a 20-year ownership period due to lower long-term energy and maintenance. MRL elevators offer energy savings in operation. However, their maintenance costs are typically higher due to more moving parts and increased complexity, similar to traction elevators. Repair costs for MRLs can also be higher and take longer due to part availability. Many components require manufacturer refurbishment or repair.

| Cost Category | Traction Elevator | Hydraulic Elevator |

|---|---|---|

| Energy Consumption | 15-30% less electricity than hydraulic, especially with regenerative drives | Higher due to continuous operation of hydraulic pump |

| Annual Maintenance Cost | $1,500 – $3,000 | $1,000 – $2,000 |

| Potential Repair Costs | N/A | Hydraulic fluid replacement and leak repairs can add $5,000+ per incident |

| Total 20-Year Ownership Cost | More cost-effective due to lower long-term energy and maintenance | Higher due to higher energy use and potential expensive repairs |

Each elevator type serves specific architectural and functional demands, offering unique advantages. Traction systems excel in speed and height. Hydraulics offer simplicity for lower rises. MRLs provide a modern, space-efficient solution. Selecting the right vertical transportation system requires careful consideration of a building’s specific requirements and operational goals.

FAQ

Which elevator type is most energy-efficient?

MRL elevators, especially with regenerative drives, offer significant energy savings. They use advanced motor and control technology.

What elevator is best for a high-rise building?

Gearless traction elevators are ideal for high-rise buildings. They provide high speeds and can travel great heights.

Do hydraulic elevators require a machine room?

Yes, hydraulic elevators typically require a machine room. This room houses the hydraulic pump and fluid reservoir.

Post time: Nov-07-2025