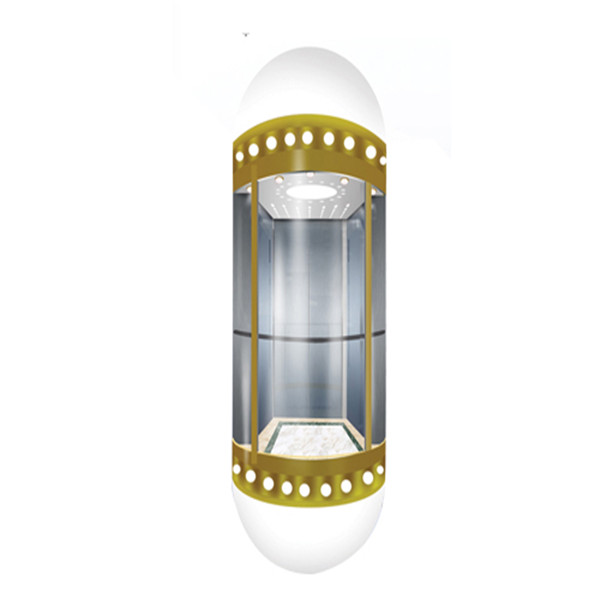

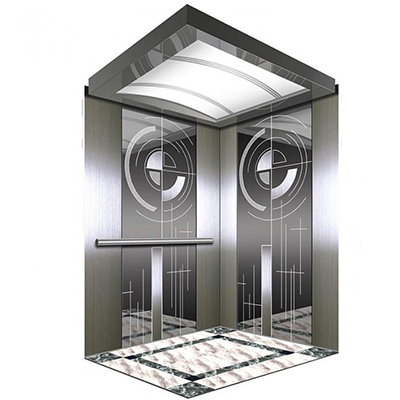

China Manufacturer of Vertical Elevator Cabin Decoration Solutions

When I think about enhancing vertical elevator cabins, the elegance of our decoration solutions immediately comes to mind. Our vertical elevator cabin decoration stands out, perfectly blending style and functionality. As a trusted manufacturer in China, we take pride in offering designs that not only elevate the aesthetic appeal but also ensure durability and safety. Whether you’re looking to transform a commercial space or enhance residential elevators, our innovative designs cater to diverse needs. I understand that buyer behavior trends show a demand for unique and customizable options, and that's what we deliver. From luxurious materials to modern finishes, we skillfully craft each cabin decoration to reflect your brand's identity. Partner with us, and let’s bring your vision to life. The quality and craftsmanship we provide are matched only by our commitment to customer satisfaction. Elevate your elevator experience with our stunning cabin decorations today!

Vertical Elevator Cabin Decoration Guarantees Peak Performance From Concept to Delivery

Vertical elevators have become an essential part of modern architectural designs, blending functionality with aesthetics. The cabin decoration of these elevators plays a crucial role in enhancing the overall user experience while also reflecting the branding and values of the building they operate in. By focusing on high-quality materials and innovative designs, businesses can ensure their elevator cabins not only perform optimally but also offer a visually appealing environment for passengers. From the initial concept phase to the final delivery, meticulous attention to detail is vital. Engaging with experienced designers and manufacturers allows for customization that meets specific client needs and preferences. This collaborative approach ensures that every aspect of the cabin — from lighting and flooring to wall finishes — aligns with the overall vision of the project, thus guaranteeing peak performance and satisfaction. As elevators operate in high-traffic areas, maintaining an impressive appearance that withstands the test of time is essential for retaining value. In today's competitive market, investing in well-designed vertical elevator cabins can significantly enhance property attractiveness. As globalization continues to shape the industry, embracing modern design trends and sustainable materials allows businesses to stand out. Ultimately, a focus on quality cabin decoration can lead to improved passenger experience, safety, and longevity, making it a wise investment for any property owner looking to elevate their space.

Vertical Elevator Cabin Decoration Guarantees Peak Performance From Concept to Delivery

| Project Phase | Key Activities | Expected Outcomes | Duration | Responsible Team |

|---|---|---|---|---|

| Concept Development | Design brainstorming sessions | Initial design concepts | 2 weeks | Design Team |

| Design Approval | Client presentations and feedback | Finalized design | 1 week | Project Manager |

| Material Sourcing | Supplier negotiations | Secured materials | 3 weeks | Procurement Team |

| Production | Fabrication of cabin elements | Completed cabin components | 4 weeks | Manufacturing Team |

| Installation | Site preparations and assembly | Installed elevator cabin | 2 weeks | Installation Team |

| Final Inspection | Quality checks and testing | Validated performance | 1 week | Quality Assurance Team |

Related Products