Top China Manufacturer of Electric Lift Systems for Efficient Solutions

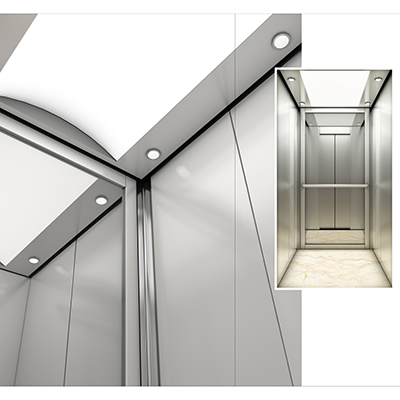

When I'm in the market for an electric lift system, quality and reliability are my top priorities. That’s why I turned to a leading manufacturer from China, renowned for their innovative solutions. Their electric lift systems are engineered to optimize efficiency and enhance productivity in various applications, from warehouses to construction sites. What I appreciate most is their commitment to quality control, ensuring each system meets rigorous standards. I also love the customization options available – whether I need a compact lift for tight spaces or a robust model for heavy loads, they’ve got it covered. Plus, the responsive customer support assures me that any questions I have during installation or maintenance will be promptly addressed. It’s clear that investing in this electric lift system is not just a purchase; it’s a step towards boosting my operational capabilities.

Electric Lift System Is The Best Now Trending

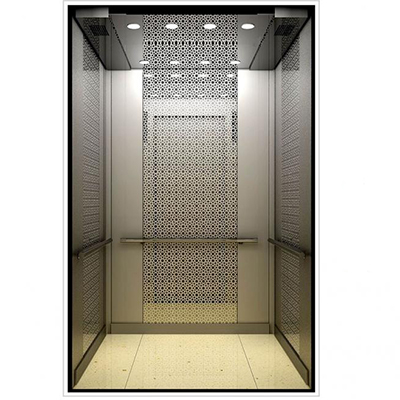

The electric lift system is revolutionizing vertical transportation, combining efficiency, safety, and environmental friendliness. As urban spaces grow and the demand for accessibility rises, these systems have emerged as a top choice for various sectors, including residential, commercial, and industrial applications. Their advanced technology ensures smooth operation, reducing wait times and enhancing user experience, making them a crucial component in modern building design. One of the key advantages of electric lift systems is their energy efficiency. Unlike conventional hydraulic lifts, which consume significant amounts of energy, electric lifts utilize a system of pulleys and counterweights, leading to lower operational costs and reduced energy consumption. This not only benefits the environment but also provides significant savings for building owners. Additionally, the ability to integrate smart technology allows for real-time monitoring and predictive maintenance, further elevating their reliability and operational efficiency. As the global market shifts toward more sustainable solutions, the electric lift system stands out as a viable investment for forward-thinking businesses and developers. With a focus on safety, eco-friendliness, and cost-effectiveness, now is the perfect time to consider integrating electric lifts into your projects, ensuring a competitive edge in a rapidly evolving industry. Embrace the trend and enhance accessibility while contributing to a greener future.

Electric Lift System Is The Best Now Trending

| Feature | Description | Advantages | Usage Areas |

|---|---|---|---|

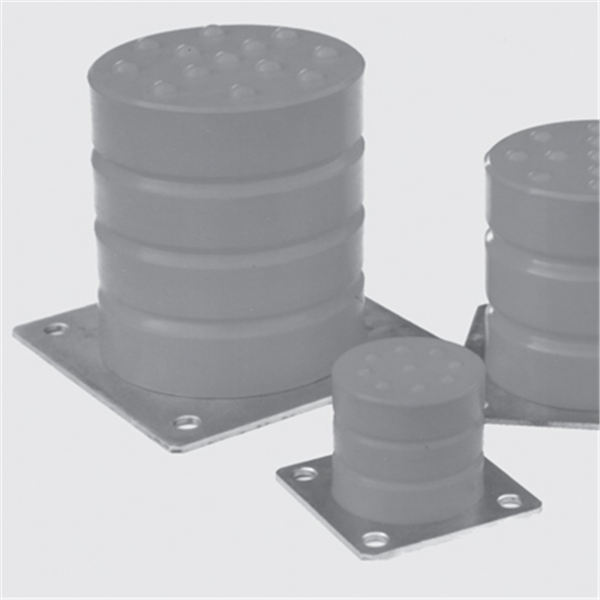

| Hydraulic System | Uses hydraulic fluid to lift heavy loads. | High lifting capacity and smooth operation. | Warehouses, construction sites. |

| Electric Motor | Operates using an electric motor for efficiency. | Energy-efficient and low maintenance. | Factories, logistic centers. |

| User-Friendly Controls | Intuitive control systems for simplifies operation. | Reduces training time for operators. | Any environment requiring lifting solutions. |

| Safety Features | Includes emergency stop buttons and overload protection. | Enhances workplace safety standards. | All industrial and commercial settings. |

| Compact Design | Space-saving models available for limited areas. | Ideal for small workshops and tight spaces. | Narrow aisles and confined spaces. |

Related Products